Steam turbine efficiency plays a crucial role in energy production and industrial processes across the globe. For engineers and consultants involved in purchasing replacement turbines, adhering to efficiency standards is essential. These standards directly influence turbine performance, reliability, operational costs, and environmental compliance. In this article, we will explore the key factors and industry benchmarks for assessing steam turbine efficiency, helping professionals make informed decisions when evaluating turbines for optimal performance.

Steam Turbine Efficiency Standards: Key Considerations for Engineers and Consultants

Table of Contents

- Introduction

- Importance of Steam Turbine Efficiency Standards

- Understanding Steam Turbine Efficiency Metrics

- Thermal Efficiency: Definition and Factors

- Isentropic Efficiency: Definition and Influencing Parameters

- Industry Standards and Guidelines

- ASME Performance Test Codes (PTC 6)

- API Standards (API 612)

- IEC Standards (IEC 60045)

- Design Innovations Enhancing Steam Turbine Efficiency

- Optimized Blade Profiles

- Advanced Materials (e.g., Inconel, Titanium Aluminides)

- Variable Nozzle Configurations

- Reduced Clearance Seals

- Factors Influencing Steam Turbine Efficiency in Replacement Turbines

- Steam Conditions and Compatibility

- Operational Load Profiles

- Integration with Auxiliary Systems

- Lifecycle Costs and Maintenance

- Environmental and Regulatory Compliance

- Efficiency and Emission Reductions

- Aligning with Global and Regional Standards

- The Role of Digital Twin Technology

- Predictive Maintenance and Real-time Monitoring

- Performance Optimization

- Lifecycle Analysis and Cost Benefits

- Case Example: Efficiency Gains with Digital Twins

- Case Studies and Benchmarking

- Success Stories in Combined-cycle Power Plants

- Lessons Learned from Efficiency Upgrades

- Conclusion

- Key Takeaways for Engineers and Consultants

- Importance of Partnering with an Innovative Manufacturer

- Your Trusted Partner in Turbine Solutions

- Overview of Company Expertise

- Commitment to Efficiency and Reliability

1. Introduction

Steam turbines remain a cornerstone of energy production and industrial processes worldwide. For engineers and consultants responsible for purchasing replacement turbines, steam turbine efficiency standards are paramount. These standards not only determine the overall performance and reliability of the turbine but also significantly impact operational costs and environmental compliance. This article delves into the critical factors and industry benchmarks for evaluating steam turbine efficiency.

2. Understanding Steam Turbine Efficiency Metrics

Efficiency in steam turbines is commonly assessed using two key metrics:

- Thermal Efficiency: Measures how effectively the turbine converts heat energy from steam into mechanical work. High thermal efficiency reduces fuel consumption and operating costs. Thermal steam turbine efficiency is heavily influenced by steam conditions, including pressure and temperature. Advanced turbines achieve higher thermal efficiency by operating under ultra-supercritical conditions (pressures above 25 MPa and temperatures exceeding 600°C), which allow for more energy extraction from steam.

- Isentropic Efficiency: Evaluates the turbine’s performance compared to an ideal isentropic process. This metric is crucial for identifying internal losses due to friction, turbulence, and other inefficiencies. Factors such as blade geometry, surface finish, and steam quality play significant roles in enhancing isentropic efficiency. For instance, high-performance turbines utilize precision-engineered blades with minimal surface roughness to reduce aerodynamic losses.

3. Industry Standards and Guidelines

- ASME Performance Test Codes (PTC 6): Specifies procedures for testing steam turbines and assessing performance against design specifications.

- API Standards (API 612): Provides guidelines for general-purpose steam turbines in industrial applications.

- IEC Standards (IEC 60045): Covers turbine design, testing, and performance evaluation, ensuring global applicability.

4. Design Innovations Enhancing Steam Turbine Efficiency

Modern steam turbines incorporate advanced design features to maximize efficiency:

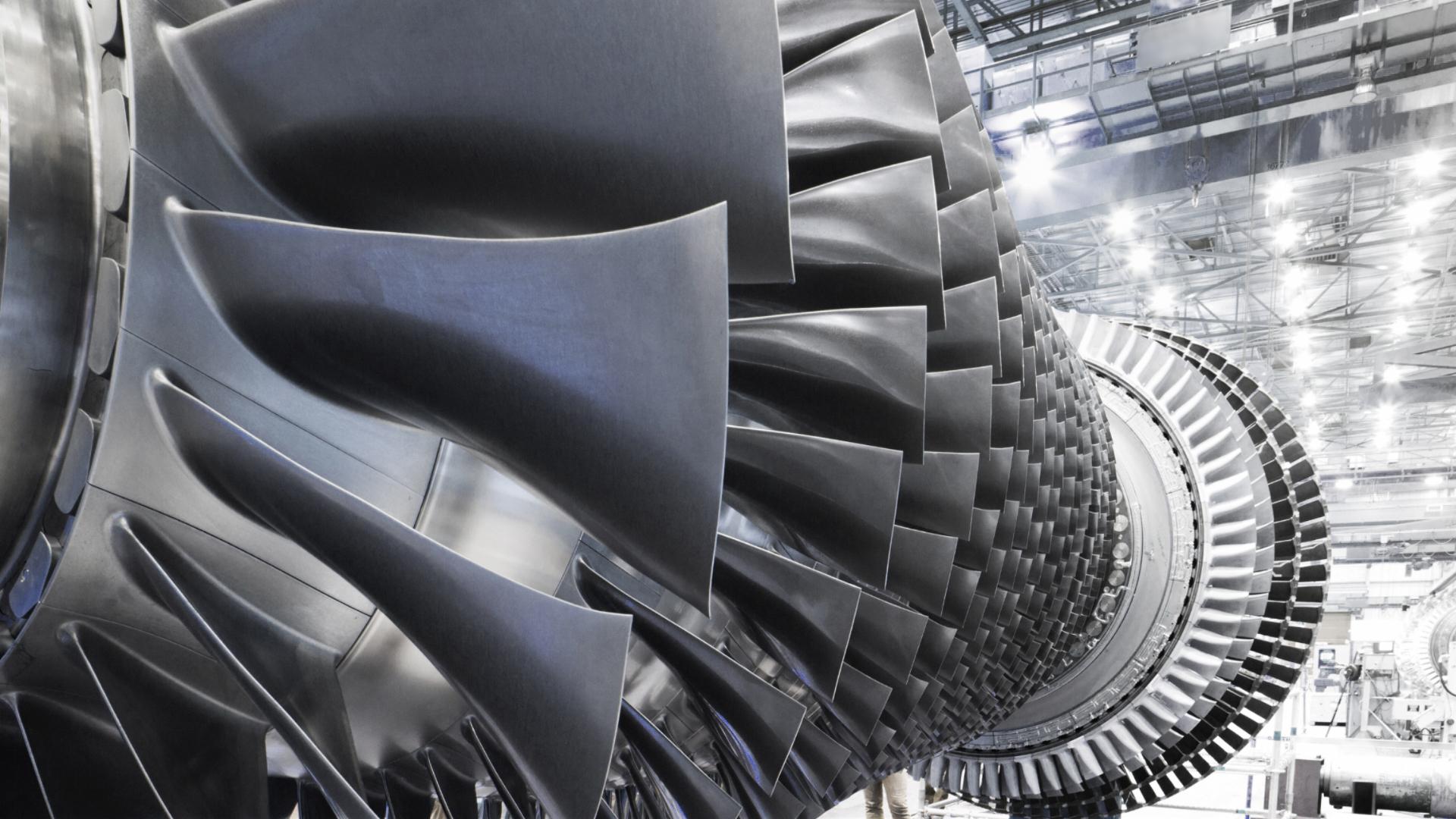

- Optimized Blade Profiles: High-performance blades with aerodynamic designs minimize losses and improve steam flow. For instance, 3D aerodynamic modelling is used to design twisted and tapered blades that optimize steam expansion and reduce secondary flow losses.

- Advanced Materials: High-strength alloys such as Inconel, a nickel-based superalloy, and titanium aluminides are frequently used in steam turbine components. These materials withstand extreme temperatures and pressures while resisting corrosion and creep, ensuring longer operational life and higher efficiency.

- Variable Nozzle Configurations: These enable precise control of steam flow. Turbines equipped with adjustable guide vanes can dynamically optimize the flow angle and volume, adapting to load variations without significant efficiency losses. This technology is particularly beneficial in combined-cycle and cogeneration plants.

- Reduced Clearance Seals: Minimizing clearance between stationary and rotating parts using advanced seals, such as brush seals or abradable seals, reduces steam leakage and boosts overall steam turbine efficiency.

5. Factors Influencing Steam Turbine Efficiency in Replacement Turbines

When selecting a replacement turbine, engineers and consultants should consider the following:

- Steam Conditions: Ensure compatibility with the plant’s existing steam conditions, including pressure, temperature, and enthalpy. For example, turbines designed for ultra-supercritical parameters will offer superior performance compared to subcritical turbines.

- Operational Load Profiles: Evaluate the turbine’s ability to maintain steam turbine efficiency across varying load conditions. High-efficiency turbines incorporate load-optimized stages that enhance performance during partial loads, a critical factor for plants with fluctuating demand.

- Auxiliary Systems: Integration with advanced auxiliary systems, such as multi-stage condensers and regenerative feedwater heaters, enhances overall thermal efficiency. Heat recovery steam generators (HRSGs) further complement turbine efficiency by utilizing waste heat from exhaust gases.

- Lifecycle Costs: Assessing lifecycle costs includes evaluating maintenance intervals, spare part availability, and expected downtime. Advanced turbines designed with modular components facilitate easier servicing, reducing operational disruptions.

6. Environmental and Regulatory Compliance

Efficiency directly correlates with emissions. High-efficiency turbines reduce greenhouse gas emissions and help plants meet stringent environmental regulations. For consultants, selecting a turbine that aligns with policies such as the Paris Agreement or regional emissions standards is a critical consideration.

7. The Role of Digital Twin Technology

Many modern turbines leverage digital twin technology to monitor performance in real-time. These systems create a virtual model of the turbine that mirrors its physical counterpart. By analyzing data from sensors embedded within the turbine, digital twins provide:

- Predictive Maintenance: Identifying potential issues before they escalate, reducing unplanned downtime.

- Performance Optimization: Real-time adjustments to operating conditions to ensure peak efficiency under varying loads.

- Lifecycle Analysis: Continuous tracking of component wear and operational trends to optimize replacement schedules and extend the turbine’s lifespan.

For example, a power plant using digital twin technology reported a 10% reduction in maintenance costs and a 5% increase in efficiency over three years. Advanced analytics and machine learning algorithms enable these virtual models to adapt and improve, ensuring that the turbine operates at its designed efficiency throughout its life cycle.

8. Case Studies and Benchmarking

Benchmarking against successful implementations can provide valuable insights. For instance, a recent upgrade at a combined-cycle power plant using advanced steam turbines resulted in a 15% increase in overall plant efficiency, saving millions in fuel costs annually.

9. Conclusion

For engineers and consultants, understanding and prioritizing steam turbine efficiency standards is essential when selecting replacement turbines. Partnering with a manufacturer that offers cutting-edge technology, compliance with international standards, and proven performance can ensure both immediate and long-term benefits.

10. Your Trusted Partner in Turbine Solutions

Our company specializes in designing and manufacturing steam turbines tailored to your plant’s specific needs. With decades of expertise and a commitment to innovation, we deliver solutions that set new benchmarks in efficiency and reliability. Contact us today to learn more about our offerings.